“Enter a length and process your part… It’s just that simple!” That’s what some people say. Truth is, processing multiple hole drilling and/or tapping processes along with saw cut operations and the like can be extremely challenging to a manufacturing facility.

AutoDrill stands ready to help you solve your most complex processes with the help of our seasoned and highly professional machine builders.

Whether you are drilling and tapping holes on a rotary table in a multi-drill format or simply pushing 2×4’s down the line while pre-drilling them for an assembly process, we can help you design the perfect system for your needs.

One of AutoDrill’s owners is fond of saying that, “…many people need to commute to work every day. Not many people need a school bus or a tank to do so.”

AutoDrill offers you solutions based on your actual needs and in line with your budget.

Please CONTACT US to discuss your application and receive prompt product cost, literature and technical help.

(Below is a quick overview of just some of the material handling situations that AutoDrill can help with. Frankly, it’s to get the context out onto Google so people can find us. …Seems to have worked for you, right?)

The automatic stop/gauge and pusher system is the perfect partner to the AutoDrill line of products. Ease of setup, ease of use, and accuracy are often required and AutoDrill has a number of solutions that can help arrange just that type of set-up for you.

Imagine a world where every part comes out the same because of a reliable, automated process! With a linear measuring system and an AutoDrill, this is not just a possibility but a reality for many of our customers. One vendor we work with says, “Employees can be trained in a matter of minutes and be top performers by the end of the day.” We’ve seen it happen!

All AutoDrill products are built with features and durability that metal working shops and plants have come to expect from their equipment. We expect the same from our machine builders and only refer you to top quality, highly reliable vendors.

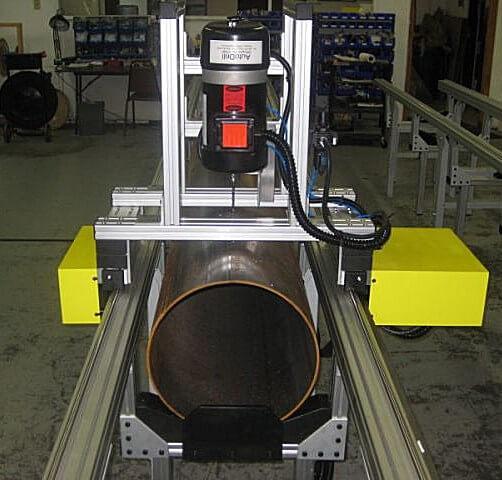

Does this mean that our machines are only good for metal applications? Not at all! In fact, they’ll work anywhere you need a tough and durable machine to perform your drilling, tapping, reaming or other hole processing job. Whether it is multiple holes in a single stroke or a single hole multiple times down the length and circumference of a filter pipe, we can help do it quickly and reliably!

How About Tables?

We have a number of vendors who we work with to provide you just the right table. Whether it is a roller table for moving parts down line quickly or a large Blanchard ground top table with a coolant trough around it for collection of chips and lubricant… We can help!

How About Mounting?

AutoDrill’s selffeeder units are built with you in mind. The housings is similar to a simple air cylinder and mounts with a series of four tapped holes and a few optional dowel pins for alignment perfection! No more struggling with round body drills and alignment issues. If you can tighten a bolt, you can likely mount an AutoDrill with no problems at all.

How About Accessories?

AutoDrill offers a wide range of accessories such as high quality key-type chucks, multiple sizes of industry standard ER style chucks, single spindle tapping heads, multi-drill spindle and tapping heads, custom threaded or bored spindles, etc. Tell us what you need. We love providing the perfect solution!

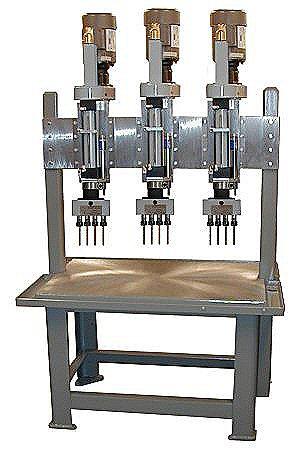

How About Multiple Piece Processing for Efficiency?

AutoDrill has provided devices to customers for processing multiple parts at a time many, many times. Often, they will have a small part and simple line them up on a table. down comes the AutoDrill with a multi-drill head and all the holes are performed in a single stroke! Can this method of multiplying the solution solve your bottleneck?

How About Moving Tubes, Channel or Other Hard to Grip Parts?

No problem! Our machine builders are experts in solving these challenges! We have witnessed our AutoDrill units being mounted to drill 48″ round pipe, 18″ tall steel rectangular tubing, flat plates of steel over 6 feet wide and the strangest looking extrusions you’ve ever seen. Sometimes the application requires that the part be moved and sometimes it’s easier to move the AutoDrill! Depending on your space requirements and constraints, the desire to meet a certain cycle time or any other limitation you can probably come up with, we can help solve it!

How About Durability?

We are smart enough to know that sometimes the down time during a machine failure costs more than the machine. That is why we build our machines to be tough!

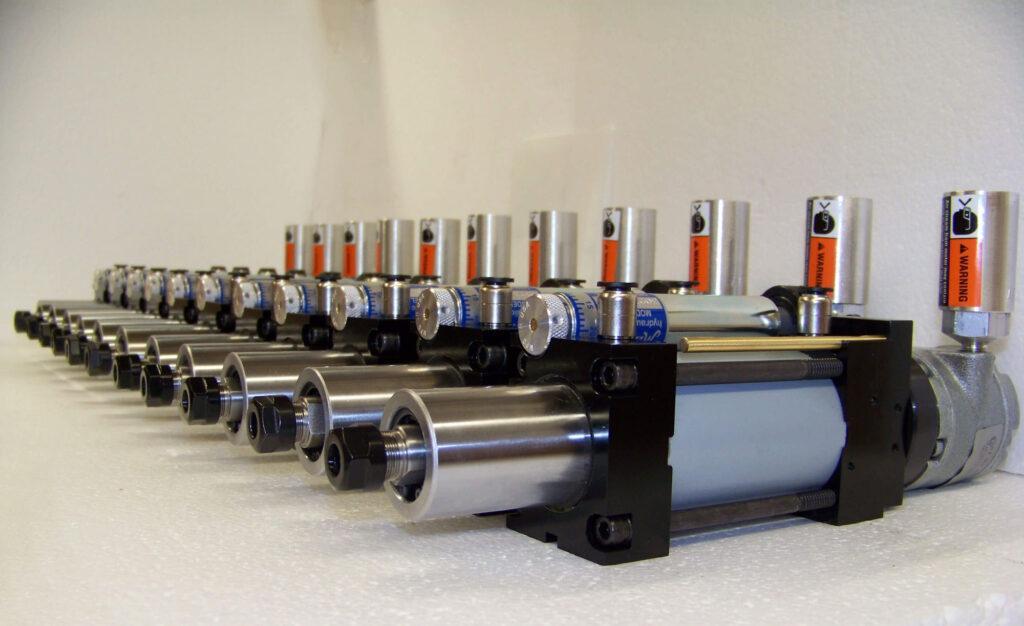

How about the heart of our selffeeder machines? The quill starts out as a solid piece of high quality steel. It is machined to the strictest of tolerances in the industry and then precision ground to fit perfectly in the cylinder tube of our machine. It is hard chrome plated for the longest possible life span. No cheap aluminum quill parts here!

How about the additional components? Well… AutoDrill took a gamble when they launched their self stroking drills. Everyone else on the market seemed to be building machines with integral valves and switches or sensors. AutoDrill decided to build the drill first and then determine how the accessories would work reliably. Because we offer half a dozen different switch and sensor options for end of stroke, proof of return and even mid or short-stroke sensing, we can often meet needs others can’t. Because our valves and controls are external, they can be mounted anywhere on your fixture that you choose to shield them from debris, possible damage from moving parts or equipment or even just to conveniently exhaust the air into a quiet box. Many components can be replaced in minutes without dis-assembly of the AutoDrill unit itself. More importantly, this means that your fixture does not need to be taken apart when a simple valve or switch is damaged somehow. We call it a “componentized” machine because all of the components are easily accessed. We took it so far as to make sure you can replace the bearings without removing much more than a belt or pulley in most cases. Down time is NOT your friend and we do all we can to keep him out of your shop!

A Wide Variety of Ways To Use an AutoDrill

AutoDrill on a Horizontal Table Set-Up

Drilling Sideways!

Approximately 30% of the AutoDrill units we sell are made to drill horizontally. This means they are generally mounted to a table top surface and either drill into a product or are sometimes static and allow the product to be moved into them. We have one particular customer who drills 36 holes per stroke this way and strokes every 10 seconds… Now that’s efficiency!

Material Pusher and a Two-Head Drilling Machine

The Customer Said, “Show me the money!”

We did! After installation of a material pusher, the customer was able to not only drill two holes per stroke, but automate the process. The machine would receive the piece to be drilled, align the drill properly and then stroke it to make two holes in one stroke. The beauty came into play when the material moved down the line to dozens of positions and automatically drilled in each one while the operator was off making money for the company by being able to focus on something else!

How About the Impossible?

It’s Stainless. It’s Coolant Free. It’s Radioactive!

In 2009, we received a call we originally thought was a prank. Drill into stainless steel. Use no coolant. Do it with an all pneumatic unit. The part you are going to drill is internally pressurized and will spray radioactive material all over your drill-unit when you pierce it. …We sold it and it worked. We told them to never, ever, under any circumstances whatsoever send that machine back to us for service. If it dies (which as far as we know, it hasn’t), we will replace it. But they had better bury it under a few hundred feet of granite in some remote desert somewhere… Because we don’t want it back! …We are still waiting for the video…

What Do You Do if Your Plasma Cutter Can’t Make the Hole?

Have a Plasma Cutter but Need To Drill Precise Holes?

A customer had a decently sized plasma table cutting out precise parts from a thick sheet of steel. But they needed to make precision round holes and the plasma simply wasn’t going to be tight enough to do that. In came the AutoDrill 5000 series with an annular cutter set up to save the day. A great video of this machine is available on AutoDrill’s YouTube Channel and Facebook page.

How About Slicing a Honey Baked Ham?

Ham it Up!!!

A few years ago, a customer called us and asked for a food service quality machine. A few days later, we had designed a machine that met their standards. It was shipped out to slowly turn and stroke a large honey baked ham while a knife spiral sliced it. So the next time you are celebrating with family or friends and eating that spiral sliced ham at the dining room table during the holidays, think of AutoDrill! …Okay, that’s a stretch, but we can try!

Hey Edward!

Hey Bella!

Get On Over Here…

A Very Stirring Experience…

AutoDrill recently designed a multiple spindle head to go into a medical facility. It took them a few days to tell us exactly what the head would be doing, but it turns out they needed a precise way to spin stirrers in small vials of blood. Apparently, nobody there was named Bella or Edward… But what did become apparent to us was that there is a shortage of devices to do this. AutoDrill to the rescue!

300,000 Holes on

One Part!?!

“That’s A Lot Of Holes!”

That’s what our engineer said when he saw the print. The customer wanted to drill well over 300,000 holes in a single part. The part was stainless, the holes were small and the material was relatively thin. …No problem. We offered a multi-spindle drilling head for the customer’s large bed CNC and they sped up their process many, many times over! They are considering a purpose-built machine if they ever need to perform the process in high volume. Why? Because if you have to drill 20 or more parts a day, that’s a lot of CNC time – In fact, it’s likely to be multiple CNC machines!

“That’s Gnarly Dude!”

More Than You Might Think…

Ever wonder just how many skateboards are sold each year world wide? Either did we, until we started selling multi-drill spindle heads, that is. You seen there is this four hole pattern that each and every skateboard uses to hold on a “truck.” The “truck” in turn holds on the wheels. There are two wheels per “truck” and two “trucks” per board. They come in old school and new school patterns. Sometimes they come in custom six hole patterns… Okay, that’s enough of a lesson for today. Suffice it to say, there are a LOT of skateboards sold world wide and AutoDrill is the leading manufacturer of multi-hole drilling solutions for the manufacturers. Sometimes it’s a simple four spindle head for a drill press and at other times, it’s a dual selffeeder drill set-up with dual four spindle heads, an automatic clamping solution and multiple board peck drilling options. Regardless, we’ve been told we are “west coast agro” and we totally agree! (Agro apparently means anything from really agitated to totally gnarly… er… cool.)

Some Additional Examples of Products Made with AutoDrills:

| Armor Tech. | Motorcycle Parts |

| Automotive Parts | Musical Instruments |

| Birdhouses | Oilfield Mats |

| Bleachers | Oilfield Products |

| Boat Maintenance Tools | Pallets |

| Bomb Demilitarization Devices | Paper Drills |

| Bridge Components | Patio Covers |

| Cabinets | Pedal Boards |

| Candles | Peg Boards |

| Caskets | Perforated Pipe |

| Ceiling Fans | Perforated Plates |

| Commercial Freezers | Plastic Extrusions |

| Commercial Refridgerators | Playground Equipment |

| Consumer Deck Boards | Railings |

| Custom Firearms | Railroad Ties |

| Delumpers | Rakes |

| Display Systems | Rifles |

| Doors | Rubber Mat Drills |

| Drawer Pulls | Safety Railings |

| Drums (musical and chemical) | Scaffolding |

| Electronic Devices | Screw Conveyors |

| Exercise Equipment | Security Fasteners |

| Farm Equipment | Shamplazas |

| Fence Posts | Shelving |

| Filter pipe | Shovels |

| Fitness Equipment | Shredders |

| Floorboards | Shunts |

| Flow Drilled Parts | Shutters |

| Furniture | Signs |

| Greenhouse Systems | Skateboards |

| Gun Stocks | Snowboards |

| Handguns | Specialized Castings |

| Harley Davidson Motorcycles | Storm Protection Devices |

| Hinges | Structural Steel Products |

| Hoes | Temporary Road Pallets |

| Honey Baked Hams | Tents |

| HVAC Components | Toys |

| I-Beam Braces | Trailer Bodies |

| Log Cabin Components | Trailer Flooring |

| Longboards | Upper Receivers |

| Louvers | Various Perforated Products |

| Lower Receivers | Welding Gun Cleaners |

| Lumber Mats | Windows |

| Lumber Processing | Wine Racks |

| Lump Busters | Wooden Reels |

| Marine Products | Yacht Components |

Some Wasteful Things That AutoDrill Can Help Eliminate:

- Underproduction – You can’t make them fast enough. (We can help you make only as much as you need, when you need it. Quickly and efficiently!)

- Overproduction – You can’t control how many are being made so they make way, way too many. (Because AutoDrill units are efficient, reliable and predictable, you can schedule your workloads more appropriately.)

- Lack of Inventory – You want to keep parts in stock, but creating them takes valuable time or your supplier is too slow. (What if you could make an entire batch in a single day that lasted a month or longer?)

- Too much Inventory – Because you want to be prepared, you buy or make too many parts at once and pay to store stationary items for long periods of time. (If you could make them quickly, you could make them as you need them.)

- Distance – Because you need to be set up a certain way, you can’t keep the parts or tools close to where they are needed. (What if each part came off an AutoDrill set-up and went right to where it was needed? No storage, no travel, no waste.)

- Time Wasted – Materials are simply not available when they are needed or there is a poor balance of work causing down time. (AutoDrill can help you catch up when a suppler runs late or get ahead and build a buffer.)

- Transportation – As one expert puts it, “long moves, re-stacking, pick up/put down” (AutoDrill machines can be built to go right in line with others. When a part is done at station #1, it goes to the AutoDrill at station #2. when it is done at the AutoDrill, it goes to station #3.)

- Massive Amount of Process Time – You simply have too much going on. Work in progress keeps everyone busy and you can’t focus on or even identify problems because of it. (Many AutoDrill set-ups allow you to push a button and walk away or process something else while the AutoDrill does all the hard work for you. Sequencing of steps, integration with PLC controls and more are all possible.)

- Defects – Products made wrong. Products made again. Wasted material and labor. The wrong design was implemented in your set-up and you have a slow-down or bottleneck on the process. (With many of our products, we can totally eliminate stack up errors, wrong measurement mistakes and even solve time constraint issues.)

If you would like to learn more about how AutoDrill products can be part of your factory wide automation project, give us a call or shoot us an email. We will get right back to you. We are always happy to have an in depth discussion about how our systems may work in your environment with your specific application. No obligation quotations are sometimes available on the spot.

Please CONTACT US to discuss your application and receive prompt product cost, literature and technical help.