For those of you in the metalworking or even woodworking industries, there are common terms and items that are easily recognizable. They might include:

- Morse Taper

- Jacobs Taper

- R8 Taper

- CATxx or ISOxx taper

- etc.

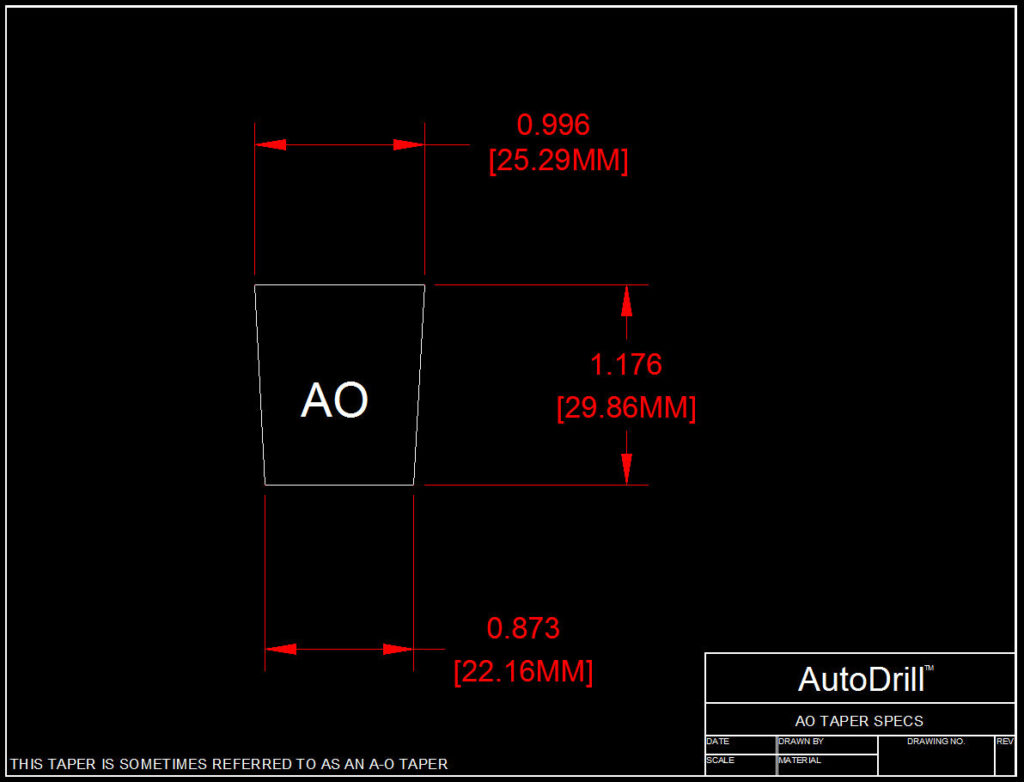

Now… Without going to Google and cheating, do you know what an AO taper is – sometimes called an A-O taper? Either did one of our engineers when he received a call in mid-2012 from a customer looking for a unique solution to their manufacturing situation. He hung up the phone, turned to the other engineers in the room and said, “What in the world is an AO taper?” …It took us a few minutes to find some data on it but took a week or so to actually get accurate specifications on the taper for the project. It seems everyone in the industry had hand-drawn specification drawings from the 1940’s and 1950’s only.

Here is what we eventually settled on – and what worked perfectly for the customer:

The customer creates optical lenses for various industries. Well, part of their process is to work on the lenses in a way we can’t describe because it’s proprietary, but involves an AutoDrill product with an AO taper spindle.

The basic steps that take place in their facility include:

- Drill out cores from raw material using a core drill that is 8″ long and 1″ in diameter

- Slice the core into wafers so they can be processed as individual parts later

- Generate or form the optical lenses from the wafers

- Bevel the edges with a special beveling tool

This customer creates lenses out of sapphire, glass, plastic and quartz. The tooling they use is generally diamond impregnated and they even do some of the coating processes in house.

Please CONTACT US to discuss your application and receive prompt product cost, literature and technical help. We are now very familiar with the AO taper and can assist you in your optical processing needs.