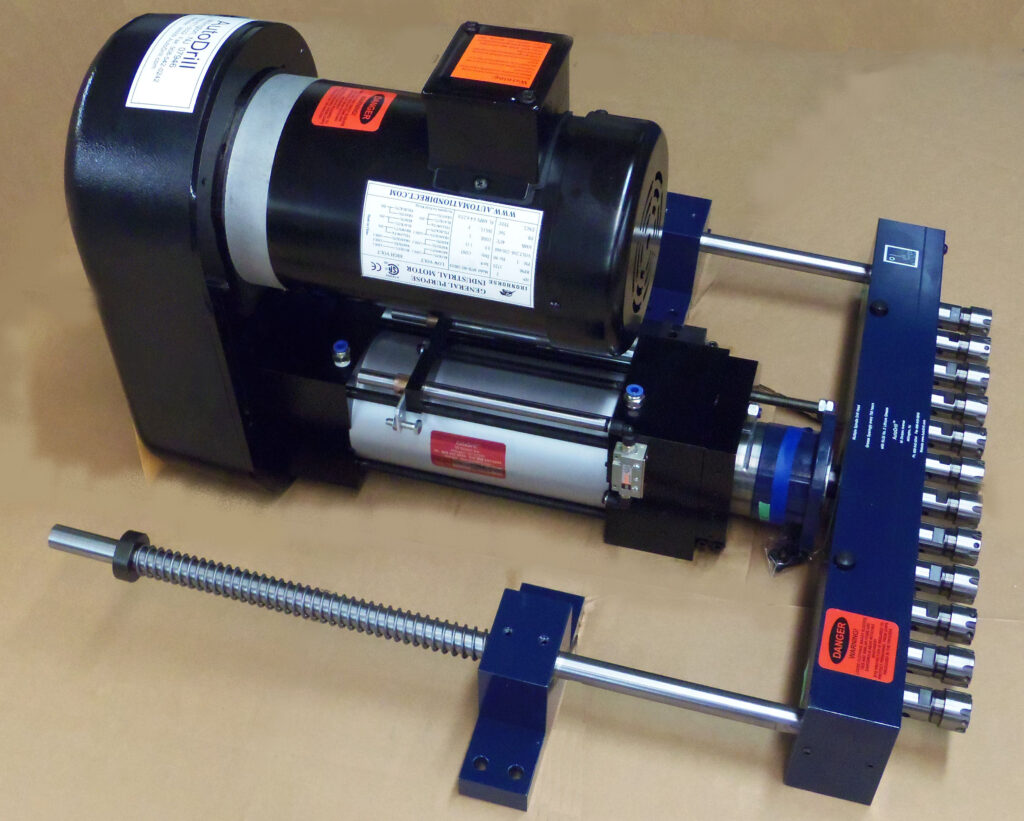

5000 Series AutoDrill (Heavy-Duty)

The 5000 AutoDrill series is offered for heavy duty or large hole operations or when the most robust and reliable unit is necessary. The features on the 5000 series unit make it very simple to maintain and operate. Its adjustment methods are easy to understand. Although it is an extremely capable unit, many find it extremely simple to use. Typically, a customer will ask for a standard electric motor drive and the unit is stroked by a small volume of shop air. This keeps the operating costs to a minimum. Because of its efficiency, your costs are kept low. Whether this helps you make more product in the same amount of time (cost savings) or simply helps you to keep up with high volume requests (higher production), the 5000 series self-feeder unit is an excellent choice.

Some of the many uses for the 5000 AutoDrill series are:

- Plate and structural steel hole drilling operations

- Pipe drilling

- Drilling multiple holes with a single unit

- Flow Drilling or Form Drilling of holes

- High thrust applications (up to 1000 lbs. on standard shop air)

- Deep hole operations up to 6.000″

- Depth controlled drilling applications

- Operations requiring all position mounting

- Operations requiring through the spindle coolant

- Large Morse Taper tooling requirements

- Available with air motor drives for explosion-proof operations using inert gas

Some of the main features of the Series 5000 unit are:

- Self feeder drill abilities

- Can receive and drive multi-head devices

- Your tool speeds from 80 to 4000 RPM

- Drill unit stroke from minimum to 6.000″

- Up to 6.000″ of Hydro Speed feed control

- Custom configurations for close center to center drilling

- Built in adjustable depth control

- Can be mounted to operate in any direction

- Standard Jacobs style key chuck in 0.500″ or 0.750″ capacity

- Precision ER collet style chuck (ER16, ER20, ER25, ER32, Custom)

- Specially made spindles are often available for your custom tooling

- Electric or Pneumatic (air) motor drives up to 3 HP standard