The History of AutoDrill LLC

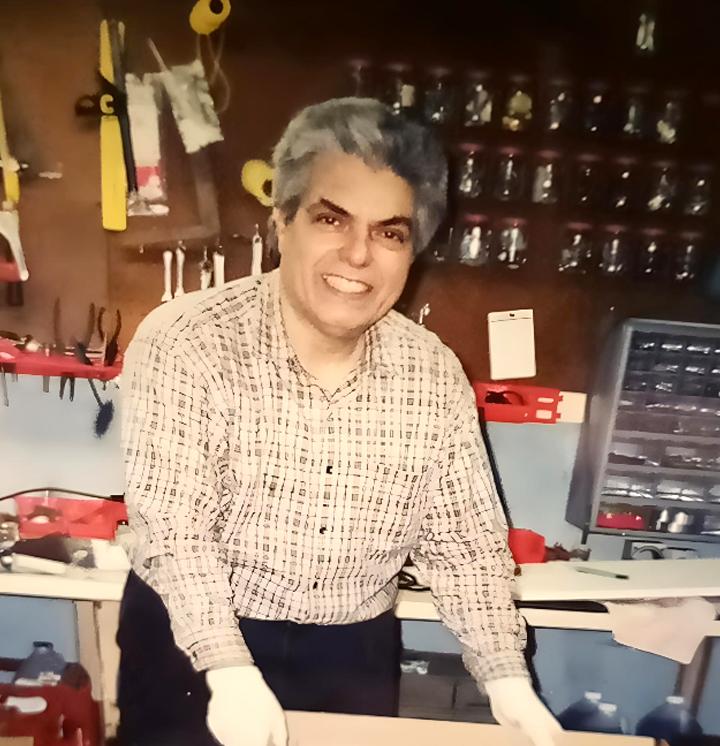

OUR FOUNDER

AutoDrill founder, Joe Agro, Sr., was born and raised in Brooklyn, New York. He was a graduate of the Polytechnic Institute of Brooklyn. He received his Bachelor of Science Degree in Chemical Engineering in 1968. He spent most of his life living in New Jersey after moving from Brooklyn to settle in the suburbs in 1969. Joe worked in the Plastic Recycling field and several other self-employed businesses. In 1999, he founded AutoDrill LLC. in his home garage! Joe Agro’s business philosophy was based on exceptional service, selection, quality, and value. Having already acquired decades of experience in the machinery field and leading other companies to success, AutoDrill stands as the leading expert for production drilling, tapping, and all things Multiple Spindle Head related!

- Late 1990’s –

- The AutoDrill design was created.

- The first prototypes were extremely successful. This would lead to the development of the AutoDrill 1000 + AutoDrill 2000 self-feed drills.

- The AutoDrill design was created.

- July 12th, 1999 –

- Joe Agro, Sr. Founded AutoDrill!

- 1999 –

- Launch of the 2000 + 2100 Series AutoDrill

- The 2000 and 2100 series AutoDrill self-feeder units are the most common units sold by AutoDrill. Capable of performing small to medium size hole processes, they are relatively light, compact, and yet powerful enough for some of the most demanding applications. These models can be found in industries ranging from food service to aerospace and military applications to the medical field.

- Launch of the 1000 + 1100 Series AutoDrill

- The 1000 and 1100 series AutoDrill self-feed units are provided when a customer has a space constraint within their process. Designed to be extremely compact and lightweight, the 1000 and 1100 series units fit where no other drill on the market can. They often outperform units that are much larger. This unit is a favorite of engineers in the medical and small appliance field, especially when working in aluminum, plastic, and fiberglass-filled products.

- Launch of the 2000 + 2100 Series AutoDrill

- 2000 –

- Launch of the 2000 Series Auto-Tap Unit

- The 2000 series Auto-Tap unit was the first product offered by AutoDrill as a self-feeding tap machine. It can tap reliably in a wide range of materials and sizes. With a range from ⅓ HP to 2HP and 100 RPM to 2000 RPM, the unit is extremely versatile.

- 2200 Series AutoDrill become available

- The 2200 Series AutoDrill was designed as a quill feed unit with a simple pull-style feed control. What this means in the customer’s shop is that a stop does not need to be placed on the fixture for the feed control. It is fully integrated into the AutoDrill design. This is a tremendous advantage when you have a multiple spindle head in the way or cannot place a stop conveniently in your AutoDrill set-up.

- Development of pneumatic controls division

- AutoDrill began offering relatively simple pneumatic controls with its units so that customers, machine builders, and dealers could have a one-stop source for their machines with simple controls. Whether it be a simple stroke control, or a control integrated with a Programmable Logic Computer (PLC), clamps, sequencing of multiple units, etc. AutoDrill can often help.

- Launch of the 2000 Series Auto-Tap Unit

- 2001 –

- Development of electrical panel controls division

- To keep up with the continued growth in cutting-edge technology, AutoDrill began offering electrical panels to its customers. This allows an application to be completely controlled by a computer or PLC and increases efficiency in production, quality, and control. We have since outsourced this service to professionals we trust and have a history with to better serve you.

- Development of electrical panel controls division

- 2002 –

- First integration with Key Machine Builder

- AutoDrill and a key machine builder in the USA started working together to offer higher-end set-ups and “turn-key” products for customers. Because AutoDrill wanted to focus on what it did best, it had always stayed away from building full fixture stands with clamps, linear feeders, bowl feeders, complex safety systems, etc. With this new business arrangement, customers now had a source for even the most complex fixtures, fully automated lines, etc. To this day, AutoDrill works closely with the engineers and designers there as well as several other strategic partners.

- First integration with Key Machine Builder

- 2003 –

- Joe Agro, Jr. as New Business Partner

- Joe Agro, Sr. brings in a second generation! His son, Joe Agro, Jr. enters the business as a partner. Joe Jr’s instinct for efficiency, innovation, and quality becomes one of the leading factors that continue to drive AutoDrill’s growth and success.

- Joe Agro, Jr. as New Business Partner

- 2005 –

- Facility Expansion

- AutoDrill expands its facility and relocates to Millington, NJ

- Facility Expansion

- 2006 –

- 5000 Series AutoDrill Launched

- Launch of the 5000, 5100, 5200, 5000 Auto-Tap and 5000 Annular Cutter. After years of design and testing, these self-feeders are one of our most successful product lines. With its dual integrated guide rod set-up, high thrust numbers, and high horsepower capability, all of the units in this series are serious workhorses! The 5000 series units rise above all others in their class.

- 5000 Series AutoDrill Launched

- 2007 –

- Integration with Multiple Key OEM’s

- These OEMs offer everything from material pushers and cutters to burning tables, CNC set-ups, etc. Because the AutoDrill product fits so well, these OEMs typically come to us first when they need any drilling, reaming, tapping, or other hole processing machinery.

- Integration with Multiple Key OEM’s

- 2010 –

- Product Improvements

- Control Feed Tapper Improvement: An improvement to the 2000 series Auto-Tap and 5000 series Auto-Tap design, this is our new standard. This technology allows customers to tap very small holes or tap in very soft materials without worrying about the thrust of the machine damaging the fragile threads. By providing fully adjustable feed control in both directions, the machine can be used to tap a multitude of hole sizes and thread pitches with nothing more than a simple adjustment between part runs. Many competitors force you to partially disassemble their cumbersome lead screw-based units. This improvement also allows AutoDrill to incorporate its Skip Feed option for faster cycle times and thus greater cost savings. Finally, this upgrade to the design allows AutoDrill to fully integrate its multiple spindle head tapping technology on the 2000 and 5000 series units. The Control Feed Tapper by AutoDrill is so efficient in its feed rate that it even extends tooling life over a standard pneumatic stroke drill tap set-up.

- Product Improvements

- 2015 –

- Facility Expansion

- AutoDrill expands its facility again and relocated to Lebanon, NJ

- Joe Agro, Sr. Retires

- Joe Agro, Sr. retires from AutoDrill: After more than 15 years of highly successful activity, Joe Sr. decided it was best to enjoy life a little more!

- Joe Agro, Jr. Takes Over All Operations at AutoDrill

- Facility Expansion

- 2020 –

- AutoDrill Expands its capabilities

- AutoDrill expands its capabilities: With the addition of extreme duty, high thrust and high torque units, AutoDrill began offering drilling units capable of up to 1.500” (38mm) holes in steel with standard tooling. Their tapping line can now thread holes up to 2.375” (60mm) in steel. Even larger custom solutions are offered for those who go beyond these sizes. This additional line of products allows AutoDrill to drive multi-drill spindles in greater quantity than ever before off of a single machine.

- AutoDrill Expands its capabilities

- 2022

- Facility Expansion

- AutoDrill expands and relocates to Flemington, NJ

- Facility Expansion