Often, potential customers call us with needs that we can meet in multiple ways…

A few weeks ago, a customer called and asked about drilling a single hole, over and over again into a soft piece of wood. They wanted an AutoDrill “no stroke” drilling unit so that they could mount it to a table top and manually feed the wooden part into the spinning tool. They would run this system for hours a day and the volume would depend on just how fast their “staff team member” could feed the parts. That poor employee must have become the most bored to death… Er… Ahem… Wrong direction.

After talking to the customer for about five minutes, we realized that the holes were small enough, and the tolerances “loose” enough that they essentially just needed a reliable way to spin a drill “bit” for hours a day. They would provide a guard that moved with the work piece so that the user couldn’t drill a hole in their hand (important!) as well as a way to evacuate the wood chips from the table top surface.

Other competitors on the market would have offered them a non-stroking drill that was similar to their full featured models at a slightly discounted costs (this is how people in our industry get rid of parts that don’t fit, etc!) The AutoDrill salesman was honest enough to admit that this was his first thought too. …But then he remembered making a similar custom set-up for another customer a few years ago.

Here is what we ultimately offered this new customer:

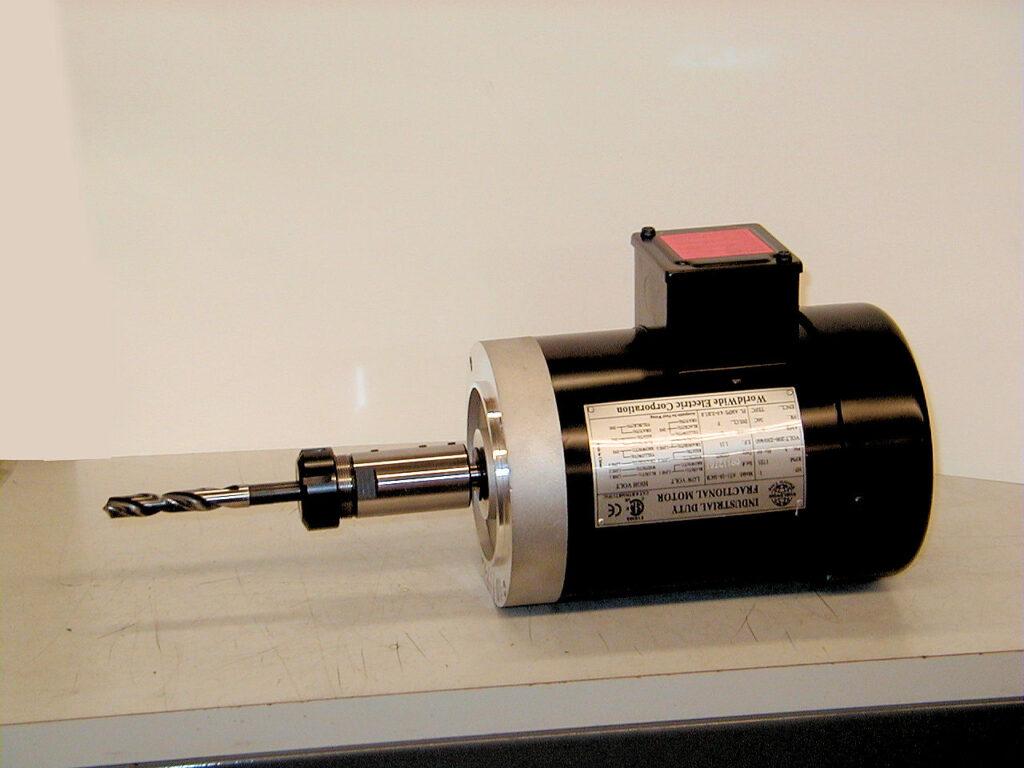

- A custom ER style chuck to mount onto the keyed 5/8″ motor shaft (less than $250)

- A simple three phase motor with a mounting base (provided by customer). Easily replaceable by the customer and certainly an industry standard item. (The item above is a sample photo and not the actual unit)

Total solution cost from AutoDrill? Well… You can do the math. We saved the customer a lot of money!

Sometimes simple is simply better!

Please CONTACT US to discuss your application and receive prompt product cost, literature and technical help.