U.S. Screw Machine Length Twist Drill Size Chart

Please CONTACT US to discuss your application and receive prompt product cost, literature and technical help.

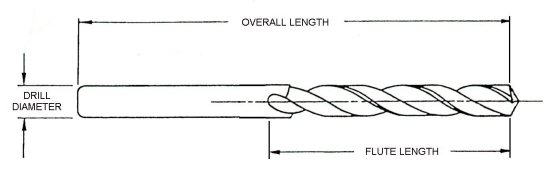

| Size | Diameter | Flute Length inch |

Overall Length inch |

||

| U.S. | Metric | inch | MM | ||

| 1.00 | 0.0394 | 1.00 | 1/2 | 1 3/8 | |

| 60 | 0.0400 | 1.016 | 1/2 | 1 3/8 | |

| 59 | 0.0410 | 1.041 | 1/2 | 1 3/8 | |

| 1.05 | 0.0413 | 1.050 | 1/2 | 1 3/8 | |

| 58 | 0.0420 | 1.067 | 1/2 | 1 3/8 | |

| 57 | 0.0430 | 1.092 | 1/2 | 1 3/8 | |

| 1.10 | 0.0433 | 1.100 | 1/2 | 1 3/8 | |

| 1.15 | 0.0453 | 1.150 | 1/2 | 1 3/8 | |

| 56 | 0.0465 | 1.181 | 1/2 | 1 3/8 | |

| 3/64 | 0.0469 | 1.191 | 1/2 | 1 3/8 | |

| 1.20 | 0.0472 | 1.200 | 5/8 | 1 5/8 | |

| 1.25 | 0.0492 | 1.250 | 5/8 | 1 5/8 | |

| 1.30 | 0.0512 | 1.300 | 5/8 | 1 5/8 | |

| 55 | 0.0520 | 1.321 | 5/8 | 1 5/8 | |

| 1.35 | 0.0531 | 1.350 | 5/8 | 1 5/8 | |

| 54 | 0.0550 | 1.397 | 5/8 | 1 5/8 | |

| 1.40 | 0.0551 | 1.400 | 5/8 | 1 5/8 | |

| 1.45 | 0.0571 | 1.450 | 5/8 | 1 5/8 | |

| 1.50 | 0.0591 | 1.500 | 5/8 | 1 5/8 | |

| 53 | 0.0595 | 1.511 | 5/8 | 1 5/8 | |

| 1.55 | 0.0610 | 1.550 | 5/8 | 1 5/8 | |

| 1/16 | 0.0625 | 1.588 | 5/8 | 1 5/8 | |

| 1.60 | 0.0630 | 1.600 | 11/16 | 1 11/16 | |

| 52 | 0.0635 | 1.613 | 11/16 | 1 11/16 | |

| 1.65 | 0.0650 | 1.650 | 11/16 | 1 11/16 | |

| 1.70 | 0.0669 | 1.700 | 11/16 | 1 11/16 | |

| 51 | 0.0670 | 1.702 | 11/16 | 1 11/16 | |

| 1.75 | 0.0689 | 1.750 | 11/16 | 1 11/16 | |

| 50 | 0.0700 | 1.778 | 11/16 | 1 11/16 | |

| 1.80 | 0.0709 | 1.800 | 11/16 | 1 11/16 | |

| 1.85 | 0.0728 | 1.850 | 11/16 | 1 11/16 | |

| 49 | 0.0730 | 1.854 | 11/16 | 1 11/16 | |

| 1.90 | 0.0748 | 1.900 | 11/16 | 1 11/16 | |

| 48 | 0.0760 | 1.930 | 11/16 | 1 11/16 | |

| 1.95 | 0.0768 | 1.950 | 11/16 | 1 11/16 | |

| 5/64 | 0.0781 | 1.984 | 11/16 | 1 11/16 | |

| 47 | 0.0785 | 1.994 | 11/16 | 1 11/16 | |

| 2.00 | 0.0787 | 2.000 | 11/16 | 1 11/16 | |

| 2.05 | 0.0807 | 2.050 | 3/4 | 1 3/4 | |

| 46 | 0.0810 | 2.057 | 3/4 | 1 3/4 | |

| 45 | 0.0820 | 2.083 | 3/4 | 1 3/4 | |

| 2.10 | 0.0827 | 2.100 | 3/4 | 1 3/4 | |

| 2.15 | 0.0846 | 2.150 | 3/4 | 1 3/4 | |

| 44 | 0.0860 | 2.184 | 3/4 | 1 3/4 | |

| 2.20 | 0.0866 | 2.200 | 3/4 | 1 3/4 | |

| 2.25 | 0.0886 | 2.250 | 3/4 | 1 3/4 | |

| 43 | 0.0890 | 2.261 | 3/4 | 1 3/4 | |

| 2.30 | 0.0906 | 2.300 | 3/4 | 1 3/4 | |

| 2.35 | 0.0925 | 2.350 | 3/4 | 1 3/4 | |

| 42 | 0.0935 | 2.375 | 3/4 | 1 3/4 | |

| 3/32 | 0.0938 | 2.383 | 3/4 | 1 3/4 | |

| 2.40 | 0.0945 | 2 1/2 | 13/16 | 1 13/16 | |

| 41 | 0.0960 | 2.438 | 13/16 | 1 13/16 | |

| 2.45 | 0.0965 | 2.450 | 13/16 | 1 13/16 | |

| 40 | 0.0980 | 2.489 | 13/16 | 1 13/16 | |

| 2.50 | 0.0984 | 2.500 | 13/16 | 1 13/16 | |

| 39 | 0.0995 | 2.527 | 13/16 | 1 13/16 | |

| 38 | 0.1015 | 2.578 | 13/16 | 1 13/16 | |

| 2.60 | 0.1024 | 2.600 | 13/16 | 1 13/16 | |

| 37 | 0.1040 | 2.642 | 13/16 | 1 13/16 | |

| 2.70 | 0.1063 | 2.700 | 13/16 | 1 13/16 | |

| 36 | 0.1065 | 2.705 | 13/16 | 1 13/16 | |

| 7/64 | 0.1094 | 2.779 | 13/16 | 1 13/16 | |

| 35 | 0.1100 | 2.794 | 7/8 | 1 7/8 | |

| 2.80 | 0.1102 | 2.800 | 7/8 | 1 7/8 | |

| 34 | 0.1110 | 2.819 | 7/8 | 1 7/8 | |

| 33 | 0.1130 | 2.870 | 7/8 | 1 7/8 | |

| 2.90 | 0.1142 | 2.900 | 7/8 | 1 7/8 | |

| 32 | 0.1160 | 2.946 | 7/8 | 1 7/8 | |

| 3.00 | 0.1181 | 3.000 | 7/8 | 1 7/8 | |

| 31 | 0.1200 | 3.048 | 7/8 | 1 7/8 | |

| 3.10 | 0.1220 | 3.100 | 7/8 | 1 7/8 | |

| 1/8 | 0.1250 | 3.0175 | 7/8 | 1 7/8 | |

| 3.20 | 0.1260 | 3.200 | 15/16 | 1 15/16 | |

| 30 | 0.1285 | 3.264 | 15/16 | 1 15/16 | |

| 3.30 | 0.1299 | 3.300 | 15/16 | 1 15/16 | |

| 3.40 | 0.1339 | 3.400 | 15/16 | 5 3/81 15/16 | |

| 29 | 0.1360 | 3.454 | 15/16 | 1 15/16 | |

| 3.50 | 0.1378 | 3.500 | 15/16 | 1 15/16 | |

| 28 | 0.1405 | 3.569 | 15/16 | 1 15/16 | |

| 9/64 | 0.1406 | 3.571 | 15/16 | 1 15/16 | |

| 3.60 | 0.1417 | 3.600 | 1 | 2 1/16 | |

| 27 | 0.1440 | 3.658 | 1 | 2 1/16 | |

| 3.70 | 0.1457 | 3.700 | 1 | 2 1/16 | |

| 26 | 0.1470 | 3.734 | 1 | 2 1/16 | |

| 25 | 0.1495 | 3.797 | 1 | 2 1/16 | |

| 3.80 | 0.1496 | 3.800 | 1 | 2 1/16 | |

| 24 | 0.1520 | 3.861 | 1 | 2 1/16 | |

| 3.90 | 0.1535 | 3.900 | 1 | 2 1/16 | |

| 23 | 0.1540 | 3.912 | 1 | 2 1/16 | |

| 5/32 | 0.1562 | 3.967 | 1 | 2 1/16 | |

| 22 | 0.1570 | 3.988 | 1 1/16 | 2 1/8 | |

| 4.00 | 0.1575 | 4.000 | 1 1/16 | 2 1/8 | |

| 21 | 0.1590 | 4.039 | 1 1/16 | 2 1/8 | |

| 20 | 0.1610 | 4.089 | 1 1/16 | 2 1/8 | |

| 4.10 | 0.1614 | 4.100 | 1 1/16 | 2 1/8 | |

| 4.20 | 0.1654 | 4.200 | 1 1/16 | 2 1/8 | |

| 19 | 0.1660 | 4.216 | 1 1/16 | 2 1/8 | |

| 4.30 | 0.1693 | 4.300 | 1 1/16 | 2 1/8 | |

| 18 | 0.1695 | 4.305 | 1 1/16 | 2 1/8 | |

| 11/64 | 0.1719 | 4.366 | 1 1/16 | 2 1/8 | |

| 17 | 0.1730 | 4.394 | 1 1/8 | 2 3/16 | |

| 4.40 | 0.1732 | 4.400 | 1 1/8 | 2 3/16 | |

| 16 | 0.1770 | 4.496 | 1 1/8 | 2 3/16 | |

| 4.50 | 0.1772 | 4.500 | 1 1/8 | 2 3/16 | |

| 15 | 0.1800 | 4.572 | 1 1/8 | 2 3/16 | |

| 4.60 | 0.1811 | 4.600 | 1 1/8 | 2 3/16 | |

| 14 | 0.1820 | 4.623 | 1 1/8 | 2 3/16 | |

| 13 | 4.70 | 0.1850 | 4.700 | 1 1/8 | 2 3/16 |

| 3/16 | 0.1875 | 4.762 | 1 1/8 | 2 3/16 | |

| 12 | 4.80 | 0.1890 | 4.800 | 1 3/16 | 2 1/4 |

| 11 | 0.1910 | 4.851 | 1 3/16 | 2 1/4 | |

| 4.90 | 0.1929 | 4.900 | 1 3/16 | 2 1/4 | |

| 10 | 0.1935 | 4.915 | 1 3/16 | 2 1/4 | |

| 9 | 0.1960 | 4.978 | 1 3/16 | 2 1/4 | |

| 5.00 | 0.1969 | 5.000 | 1 3/16 | 2 1/4 | |

| 8 | 0.1990 | 5.054 | 1 3/16 | 2 1/4 | |

| 5.10 | 0.2008 | 5.100 | 1 3/16 | 2 1/4 | |

| 7 | 0.2010 | 5.105 | 1 3/16 | 2 1/4 | |

| 13/64 | 0.2031 | 5.159 | 1 3/16 | 2 1/4 | |

| 6 | 0.2040 | 5.182 | 1 1/4 | 2 3/8 | |

| 5.20 | 0.2047 | 5.200 | 1 1/4 | 2 3/8 | |

| 5 | 0.2055 | 5.220 | 1 1/4 | 2 3/8 | |

| 5.30 | 0.2087 | 5.300 | 1 1/4 | 2 3/8 | |

| 4 | 0.2090 | 5.309 | 1 1/4 | 2 3/8 | |

| 5.40 | 0.2126 | 5.400 | 1 1/4 | 2 3/8 | |

| 3 | 0.2130 | 5.410 | 1 1/4 | 2 3/8 | |

| 5.50 | 0.2165 | 5.500 | 1 1/4 | 2 3/8 | |

| 7/32 | 0.2188 | 5.558 | 1 1/4 | 2 3/8 | |

| 5.60 | 0.2205 | 5.600 | 1 5/16 | 2 7/16 | |

| 2 | 0.2210 | 5.613 | 1 5/16 | 2 7/16 | |

| 5.70 | 0.2244 | 5.700 | 1 5/16 | 2 7/16 | |

| 1 | 0.2280 | 5.791 | 1 5/16 | 2 7/16 | |

| 5.80 | 0.2283 | 5.800 | 1 5/16 | 2 7/16 | |

| 5.90 | 0.2323 | 5.600 | 1 5/16 | 2 7/16 | |

| A | 0.2340 | 5.944 | 1 5/16 | 2 7/16 | |

| 15/64 | 0.2344 | 5.954 | 1 5/16 | 2 7/16 | |

| 6.00 | 0.2362 | 6.000 | 1 3/8 | 2 1/2 | |

| B | 0.2380 | 6.045 | 1 3/8 | 2 1/2 | |

| 6.10 | 0.2402 | 6.100 | 1 3/8 | 2 1/2 | |

| C | 0.2420 | 6.147 | 1 3/8 | 2 1/2 | |

| 6.20 | 0.2441 | 6.200 | 1 3/8 | 2 1/2 | |

| D | 0.2460 | 6.248 | 1 3/8 | 2 1/2 | |

| 6.30 | 0.2480 | 6.300 | 1 3/8 | 2 1/2 | |

| E, 1/4 | 0.2500 | 6.350 | 1 3/8 | 2 1/2 | |

| 6.40 | 0.2520 | 6.400 | 1 7/16 | 2 5/8 | |

| 6.50 | 0.2559 | 6.500 | 1 7/16 | 2 5/8 | |

| F | 0.2570 | 6.528 | 1 7/16 | 2 5/8 | |

| 6.60 | 0.2598 | 6.600 | 1 7/16 | 2 5/8 | |

| G | 0.2610 | 6.629 | 1 7/16 | 2 5/8 | |

| 6.70 | 0.2638 | 6.700 | 1 7/16 | 2 5/8 | |

| 17/64 | 0.2656 | 6.746 | 1 7/16 | 2 5/8 | |

| H | 0.2660 | 6.756 | 1 1/2 | 2 11/16 | |

| 6.80 | 0.2677 | 6.800 | 1 1/2 | 2 11/16 | |

| 6.90 | 0.2717 | 6.900 | 1 1/2 | 2 11/16 | |

| I | 0.2720 | 6.909 | 1 1/2 | 2 11/16 | |

| 7.00 | 0.2756 | 7.000 | 1 1/2 | 2 11/16 | |

| J | 0.2770 | 7.036 | 1 1/2 | 2 11/16 | |

| 7.10 | 0.2795 | 7.100 | 1 1/2 | 2 11/16 | |

| K | 0.2810 | 7.137 | 1 1/2 | 2 11/16 | |

| 9/32 | 0.2812 | 7.142 | 1 1/2 | 2 11/16 | |

| 7.20 | 0.2835 | 7.200 | 1 9/16 | 2 3/4 | |

| 7.30 | 0.2874 | 7.300 | 1 9/16 | 2 3/4 | |

| L | 0.2900 | 7.366 | 1 9/16 | 2 3/4 | |

| 7.40 | 0.2913 | 7.400 | 1 9/16 | 2 3/4 | |

| M | 0.2950 | 7.493 | 1 9/16 | 2 3/4 | |

| 7.50 | 0.2953 | 7.500 | 1 9/16 | 2 3/4 | |

| 19/64 | 0.2969 | 7.541 | 1 9/16 | 2 3/4 | |

| 7.60 | 0.2992 | 7.600 | 1 5/8 | 2 13/16 | |

| N | 0.3020 | 7.671 | 1 5/8 | 2 13/16 | |

| 7.70 | 0.3031 | 7.700 | 1 5/8 | 2 13/16 | |

| 7.80 | 0.3071 | 7.800 | 1 5/8 | 2 13/16 | |

| 7.90 | 0.3110 | 7.900 | 1 5/8 | 2 13/16 | |

| 5/16 | 0.3125 | 7.938 | 1 5/8 | 2 13/16 | |

| 8.00 | 0.3150 | 8.000 | 1 11/16>/td> | 2 15/16 | |

| O | 0.3160 | 8.026 | 1 11/16 | 2 15/16 | |

| 8.10 | 0.3189 | 8.100 | 1 11/16 | 2 15/16 | |

| 8.20 | 0.3228 | 8.200 | 1 11/16 | 2 15/16 | |

| P | 0.3230 | 8.204 | 1 11/16 | 2 15/16 | |

| 8.30 | 0.3268 | 8.300 | 1 11/16 | 2 15/16 | |

| 21/64 | 0.3281 | 8.334 | 1 11/16 | 2 15/16 | |

| 8.40 | 0.3307 | 8.400 | 1 11/16 | 3 | |

| Q | 0.3320 | 8.433 | 1 11/16 | 3 | |

| 8.50 | 0.3346 | 8.500 | 1 11/16 | 3 | |

| 8.60 | 0.3386 | 8.600 | 1 11/16 | 3 | |

| R | 0.3390 | 8.611 | 1 11/16 | 3 | |

| 8.70 | 0.3425 | 8.700 | 1 11/16 | 3 | |

| 11/32 | 0.3438 | 8.733 | 1 11/16 | 3 | |

| 8.80 | 0.3465 | 8.800 | 1 3/4 | 3 1/16 | |

| S | 0.3480 | 8.839 | 1 3/4 | 3 1/16 | |

| 8.90 | 0.3504 | 8.900 | 1 3/4 | 3 1/16 | |

| 9.00 | 0.3543 | 9.000 | 1 3/4 | 1/16 | |

| T | 0.3580 | 9.093 | 1 3/4 | 3 1/16 | |

| 9.10 | 0.3583 | 9.100 | 1 3/4 | 3 1/16 | |

| 23/64 | 0.3594 | 9.129 | 1 3/4 | 3 1/16 | |

| 9.20 | 0.3622 | 9.200 | 1 13/16 | 3 1/8 | |

| 9.30 | 0.3661 | 9.300 | 1 13/16 | 3 1/8 | |

| U | 0.3680 | 9.347 | 1 13/16 | 3 1/8 | |

| 9.40 | 0.3701 | 9.400 | 1 13/16 | 3 1/8 | |

| 9.50 | 0.3740 | 9.500 | 1 13/16 | 3 1/8 | |

| 3/8 | 0.3750 | 9.525 | 1 13/16 | 3 1/8 | |

| V | 0.3770 | 9.576 | 1 7/8 | 3 1/4 | |

| 9.60 | 0.3780 | 9.600 | 1 7/8 | 3 1/4 | |

| 9.70 | 0.3819 | 9.700 | 1 7/8 | 3 1/4 | |

| 9.80 | 0.3858 | 9.800 | 1 7/8 | 3 1/4 | |

| W | 0.3860 | 9.804 | 1 7/8 | 3 1/4 | |

| 9.90 | 0.3898 | 9.900 | 1 7/8 | 3 1/4 | |

| 25/64 | 0.3906 | 9.921 | 1 7/8 | 3 1/4 | |

| 10.00 | 0.3937 | 10.00 | 1 15/16 | 3 5/16 | |

| X | 0.3970 | 10.084 | 1 15/16 | 3 5/16 | |

| 10.20 | 0.4016 | 10.200 | 1 15/16 | 3 5/16 | |

| Y | 0.4040 | 10.262 | 1 15/16 | 3 5/16 | |

| 13/32 | 0.4062 | 10.317 | 1 15/16 | 3 5/16 | |

| Z | 0.4130 | 10.490 | 2 | 3 3/8 | |

| 10.50 | 0.4134 | 10.500 | 2 | 3 3/8 | |

| 27/64 | 0.4219 | 10.716 | 2 | 3 3/8 | |

| 10.80 | 0.4252 | 10.800 | 2 1/16 | 3 7/16 | |

| 11.00 | 0.4331 | 11.000 | 2 1/16 | 3 7/16 | |

| 7/16 | 0.4375 | 11.112 | 2 1/16 | 3 7/16 | |

| 11.20 | 0.4409 | 11.200 | 2 1/8 | 3 9/16 | |

| 11.50 | 0.4528 | 11.500 | 2 1/8 | 3 9/16 | |

| 29/64 | 0.4531 | 11.509 | 2 1/8 | 3 9/16 | |

| 11.80 | 0.4646 | 11.800 | 2 1/8 | 3 5/8 | |

| 15/32 | 0.4688 | 11.908 | 2 1/8 | 3 5/8 | |

| 12.00 | 0.4724 | 12.000 | 2 3/16 | 3 11/16 | |

| 12.20 | 0.4803 | 12.200 | 2 3/16 | 3 11/16 | |

| 31/64 | 0.4844 | 12.304 | 2 3/16 | 3 11/16 | |

| 12.50 | 0.4921 | 12.500 | 2 1/4 | 3 3/4 | |

| 1/2 | 0.500 | 12.700 | 2 1/4 | 3 3/4 | |

WHY DO MY TOOLS WEAR QUICKLY OR BREAK?

Note that excessive tool wear or breakage is often caused by one of the following:

- Improper surface speeds

- Improper feed rates

- Improper cutting tool type or material (HSS vs TiN vs Carbide, etc.)

- Dull tooling

- Hard spots in the material such as scale, silica, etc.

- Improper coolant or lubricant type

- Inadequate coolant or lubricant (overall for chip removal, rubbing, etc.)

- Inadequate coolant or lubricant (at the tip of the tooling)

- The tool is not rigid enough (try drill bushings or guides, guide rods on the drilling machine, etc.)

- Too deep of a cut without proper chip removal – Chip packing (try peck drilling, air blast or coolant through the tool options, etc.)

- Tools that were manufactured or sharpened incorrectly. (watch those clearance, rake and lip angles as well as rough surfaces, etc.)

CALCULATING CYCLE TIME WHEN DRILLING:

We can help you lower your cycle time when drilling holes in a part or multiple parts. Generally, this is the calculation we use to figure out the time it will take to perform a process:

DEPTH divided by FEED = ROTATIONS.

ROTATIONS divided by RPM = MINUTES.

MINUTES multiplied by 60 = SECONDS it takes for the process.

(DEPTH = 30% of the diameter of the tool plus the thickness of the material)

Add in stroke up to product time

Add in stroke back to home time

Add in clamp and unclamp time

Add in any human factors, etc.

Add in time for potentially dull tooling, etc.

Add in time for less than adequate machine thrust, etc.

We use the following charts to estimate these numbers:

Please CONTACT US to discuss your application and receive prompt product cost, literature and technical help.